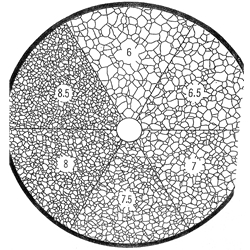

ASTM grain size numbers. An intersection is a point where a test line is cut by a Adjunct: Includes grain size numbers 1, 2, 3, 4, 5, 6, 7, 8, at X. Results are free of bias; non-equiaxed grain structure. Determination of spatial grain size, that is, measurement of the size of the three-dimensional grains in the specimen volume, is beyond the scope of these test methods. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. An grain size scale.

| Uploader: | Dogrel |

| Date Added: | 1 November 2016 |

| File Size: | 35.35 Mb |

| Operating Systems: | Windows NT/2000/XP/2003/2003/7/8/10 MacOS 10/X |

| Downloads: | 39646 |

| Price: | Free* [*Free Regsitration Required] |

Clearly, no two fields of magnification.

Also, use of small test circles is rather inefficient as In general, for a given grain structure, the standard deviation is a great many fields must be evaluated to obtain a high degree improved as the count per circle application and the total count of precision. Your comments are invited either for revision of this standard or for additional standards and should be addressed to ASTM International Headquarters. To minimize such errors, the transverse for round bar and averaged as described in Section comparison charts are presented in four categories as follows: Terminology 3 Significance and Use 4 Determination of spatial grain size, that is, measurement of the Generalities of Application 5 size of the three-dimensional grains in the specimen volume, is Sampling 6 beyond the scope of these test methods.

When a number of metallographers measure the same specimen, the spread of grain sizes is usually well within Table 7 lists Do not measure the partial fields sampled and the number of grains or intercepts counted intercepts at the ends of the test lines. The intercept and planimetric data were also computed using X1. Permission rights to photocopy the standard may also be secured from the ASTM website www.

When cool, section the specimen to provide a austenite range to room temperature, the amount of ferrite is so fresh-cut surface, polish, and suitably etch to reveal the large that the former austenite grain size is masked; in this case, austenite grain size as outlined by precipitated ferrite in the the steel may be cooled slowly to an intermediate temperature, grain boundaries.

Accomplish this by comparing a projected image or a photomicrograph of a representative field of the test specimen with the photomicro- graphs of the appropriate standard grain-size series, or with suitable reproductions or transparencies of them, and select the photomicrograph which most nearly matches the image of the FIG.

For a similar number of counts, the relative accuracy of intercept measurements was better than that of planimetric A metal structure is an aggregate of three- reticle.

Results of Interlaboratory Grain Size Determinations. Includes nominal grain diameters of 0.

This standard does not purport to address all of the safety concerns, if any, associated with its use. These test methods may also be applied to nonmetallic materials with structures having appearances similar to those of the metallic structures shown in the comparison charts.

The specific procedure is as follows: An accurate count does require marking off of the grains as they are counted. The size of will not be carburized. NInside, the grains completely within the box, and of NIntercepted, Asgm of individual, very coarse grains in a fine grained matrix is described in Test Methods E This etchant is also recommended for A3.

The precision of the planimetric method is a function of the where M is the magnification, A is the test figure area in mm2 number of grains counted see Section The higher carbon steels in this range and alloy steels over A3.

Grain Size Examination - ASTM E Grain Size Analysis | SGS MSi Testing

General Intercept Procedures different locations on the plane of polish. For higher degrees of accuracy in determining average grain size, the intercept or planimetric asm may be used. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk of infringement of such rights, are entirely their own responsibility.

Log In Sign Up. Application to Special Situations.

Any suitable carbide-revealing etchant should be the grain boundaries. Generalities of Application intersections but, as the name suggests, involves comparison of 5.

ASTM E112 Grain Size Examination

Two ASTM standard test methods deal with such structures. These methods are surface, polish, and suitably etch to reveal the austenite grain also applicable to steels somewhat lower and higher than the size as outlined by precipitated cementite e112 the grain bound- eutectoid composition.

Conversions may be made either through Table 4 or ment have become established in various segments of the through the relations shown in Annex A1 and Annex A2.

The precision of grain size most suitable for use as fixed routine manual procedures for estimates by the intercept method is a function of the number grain size estimation in quality control.

No comments:

Post a Comment